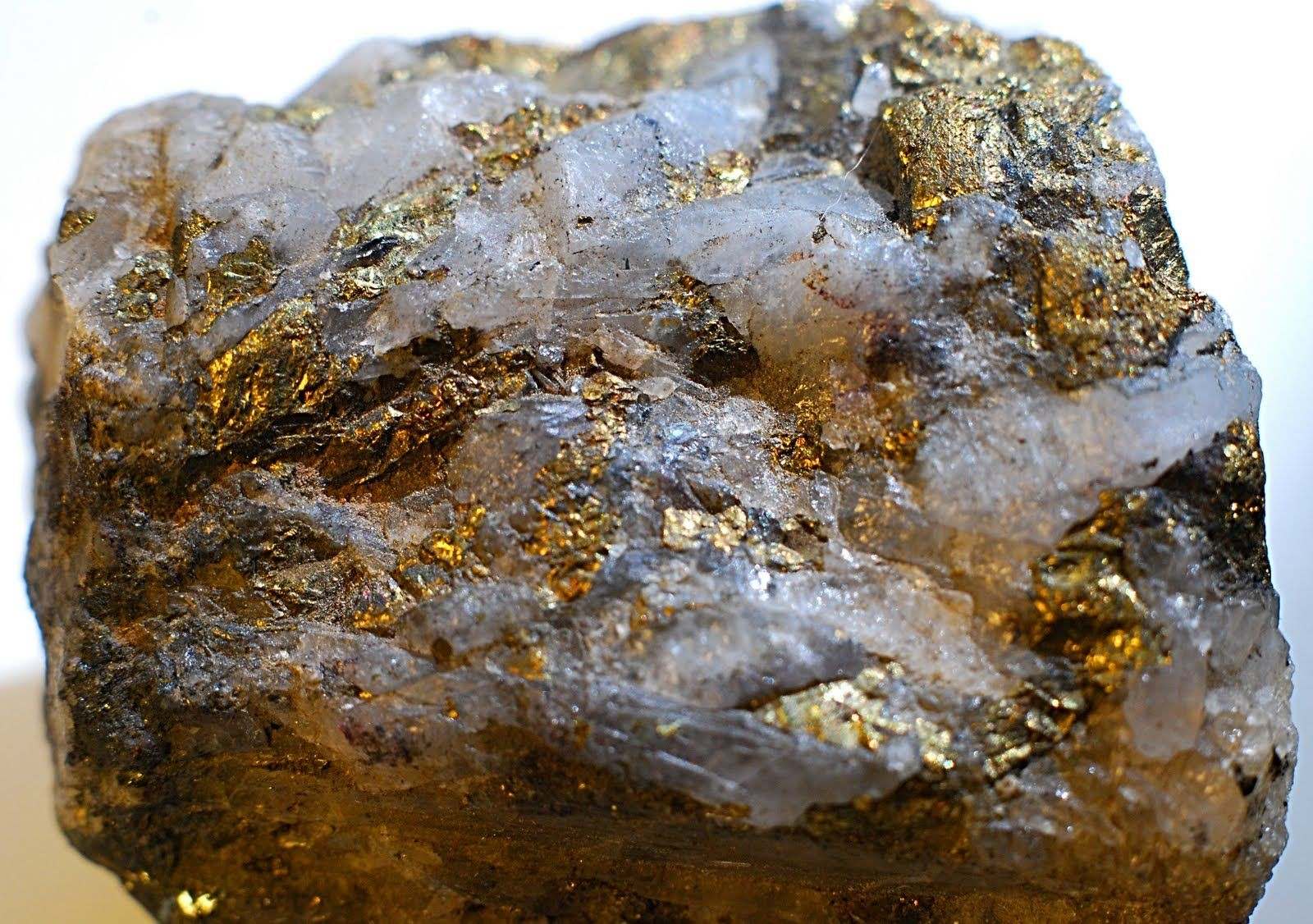

Gold

Capabilities

Process Development and Design

Contemporary process design and implementation techniques require innovative and proven strategies that add value throughout various stages of the project's lifecycle.

Research and Engineering Solutions

By prioritizing early-stage collaboration with clients in engineering services and emphasizing front-end-loaded engineering, projects can ensure the soundness of technical decisions and designs, leading to the selection of the most economical option.

Comminution, Gravity Separation and Flotation

A proficient technical design team well-versed in various comminution technologies, such as crushing, conveying, grinding, gravity-gold separation, and classifying, is invaluable. Given the rise of intricate polymetallic deposits, having a team skilled in flotation across a wide array of minerals can significantly impact the project's success.

Pretreatment of Refractory Gold Ore

The treatment of refractory gold ore, whether in whole ore form or as flotation concentrates, has gained significant attention since the 1980s. Many gold findings now involve ores that are either entirely or partially refractory. Pre-treatment methods for refractory ores encompass pressure oxidation, biological oxidation, and different roasting techniques. Design teams well-versed in these three pre-treatment processes can enhance the overall value of a project.

Recovering and Refining Gold

Businesses require effective recovery strategies with utmost care to boost profits. By assembling teams well-versed in cyanide-in-leach (CIL), cyanide-in-pulp (CIP), carbon elution, and carbon activation, along with expertise in newer thiosulfate leaching and regeneration methods, gold recovery and profitability can be significantly improved.

Designing and Specifying Equipment

The profitability of a mining company can see notable enhancements through meticulous equipment selection and well-thought-out design processes. Our patented equipment designs have successfully improved operations, maintenance, and the efficiency of units tailored for specific process operations worldwide.

Industry challenges

The global gold production landscape has transformed in the last three decades.

The discovery of substantial, easily processed gold reserves in key mining regions has dwindled.

Mining firms are grappling with a challenging choice: should they tackle extensive, low-grade deposits or seek out smaller, more intricate ones in remote, difficult-to-access areas?

Adding complexity, these ore bodies are often refractory, where gold is trapped within sulphide minerals, or double refractory, with gold bound in sulphide minerals and preg-robbing due to organic carbon, requiring pre-treatment before leaching.

Recent years have seen a shift in mining strategies from those tailored for high-grade underground deposits to those suited for low-grade, open-pit, polymetallic deposits. Additionally, significant free-milling gold operations are encountering increasingly refractory deposits.

Given the scale, intricacy of the ore bodies, and remote settings, mining enterprises now require a deeper understanding of mineralogy and the advantages of various extraction methods.

Presently, companies are trimming expenditure on developing new mineral deposits and focusing on refining existing mines and production sites.

Our assistance can make a difference.